Leading Japanese flat knitting machine and design systems manufacturer Shima Seiki has launched a brand-new Virtual Sample Instagram page – https://www.instagram.com/virtualsample). And as you would expect from the name, the company’s Virtual Sample Instagram page is dedicated to one of its biggest contributions to sustainable fashion – virtual sampling.

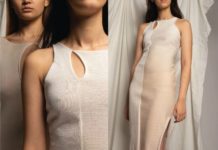

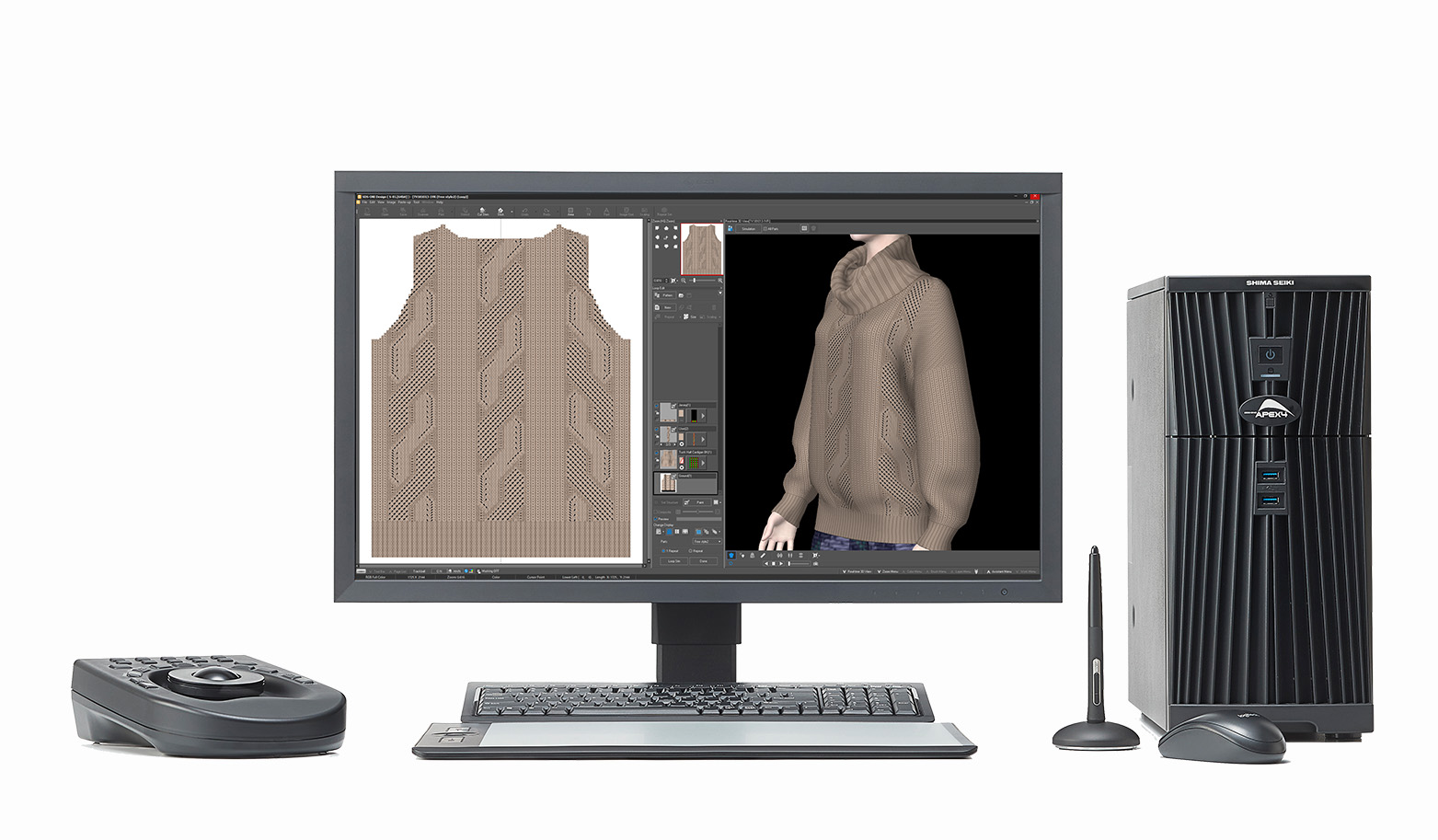

Virtual sampling is based on realistic simulations generated on Shima’s SDS-ONE APEX series design system, aimed at replacing actual production samples in the sample-making process, which is known as one of the biggest sources of waste in the apparel industry. Via the new Instagram page, Shima introduces various examples of virtual samples in both 2D and 3D to show just how realistic its simulations can actually be. Posts consist of original Shima Seiki designs, as well as reposts from other APEX series users.

“We are using social media as a new medium to reach out to potential users who may not know about Shima Seiki, or our SDS-ONE APEX series design system or its true capabilities. We also wish to raise awareness for sustainable manufacturing through the use of virtual samples, made possible in part by our ultra-realistic 2D and 3D simulation capability” commented Shima Seiki’s Head of Marketing Masaki Karasuno.

Realistic fabric simulation

“We have also heard that many designers working with other 3D simulation software are unhappy with the lack of realism offered by their simulation quality. Through our Instagram page we wish to reach out to those people in hopes that they’ll discover our APEX series to be a better alternative, especially in fabric simulation,” Mr Karasuno explains.

Shima is keen to highlight the difference between its design system and other software. Masaki Karasuno explains: “While other software relies on mapping photos of actual fabrics, which incidentally require initial sample making, or other 2D images or flat illustrations of textile designs, our simulations begin with the smallest denominator – the yarn or thread.”

“Actual yarn can be scanned-in or generated together with such details as nap or fuzz. This is then virtually knitted or woven into fabric based on actual machine programming data while taking into account such details as yarn and thread count, yarn ends and stitch density.”

“Simulations using real yarn and real machine data yield real-looking virtual samples. It’s a simple formula, and only Shima Seiki has the know-how. What’s more, because of the aforementioned connection with machines, as soon as the virtual sample is approved the design can go directly to production. That is another complaint we often hear about other software—lack of connectivity.”

Shima Seiki has over 20 years of experience in virtual sampling. From way back Shima was promoting it as an alternative to actual sample making for reducing the enormous impact on time, cost and wasted material in the fashion supply chain. This was back in the days before sustainability was ever an issue, so you can imagine how difficult it was to convince designers to use it. It was equally difficult to convince apparel companies to accept virtual samples.

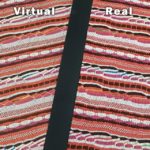

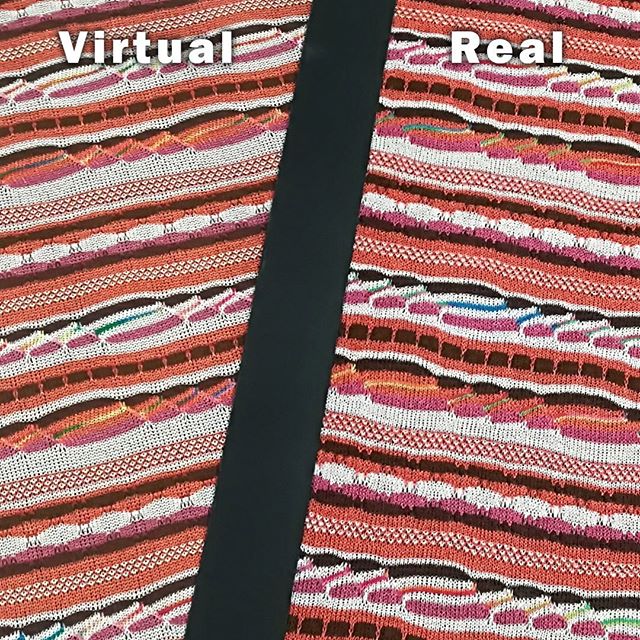

Masaki Karasuno elaborates: “Over the years our virtual sampling technology has evolved to become so realistic, with some samples it’s actually impossible to tell the difference between real and virtual until you feel it. And now that sustainability has finally become an issue, everyone is eager to find out more about this virtual sampling issue Shima Seiki has been talking about for all these years.”

View more virtual samples…

“When it comes to virtual samples however, one tends to think that it’s the ‘virtual’ part that’s important―that is, the visually impressive, “realistic”-looking 3D portion that everyone is amazed by and wowing over. Of course, that remains an important part of the equation, but from our experience we believe that it’s the ‘sample’ portion that is key. What takes more convincing for apparel companies to accept virtual samples as alternatives to actual sample making―which is the whole point here―is the fabric detail of the sample itself rather than the overall shape,” Mr Karasuno continues.

“Most apparel companies we approached at the initial stages of virtual sampling were reluctant to accept simulations as part of their evaluation process because they felt the need to actually touch and feel the texture of the fabric. How realistically can texture detail be reproduced, is therefore the key to successfully implementing simulations into the supply chain, and we believe we are the most successful at it.”

“If you haven’t seen what the APEX series can do, or haven’t seen it in a while, we highly recommend a demonstration. And be sure to follow us on Instagram!”

More Shima Seiki social media

Shima has also launched two more social media initiatives – a WHOLEGARMENT Official Instagram page and its own Shima Seiki Official Facebook page.

Instagram – WHOLEGARMENT Official

The official WHOLEGARMENT page on Instagram gives with basic information about seam-free, sustainable WHOLEGARMENT knitwear, focusing on its many benefits as they appeal to consumers – https://www.instagram.com/wholegarment_official

Facebook: SHIMA SEIKI Official

The official Shima Seiki Facebook page features the latest reports on products and exhibitions as well as other updates not found on the Shima Seiki Website – https://www.facebook.com/shimaseiki.official

Subscribe To Our Newsletter

Join our mailing list to receive the latest news and updates from our team.