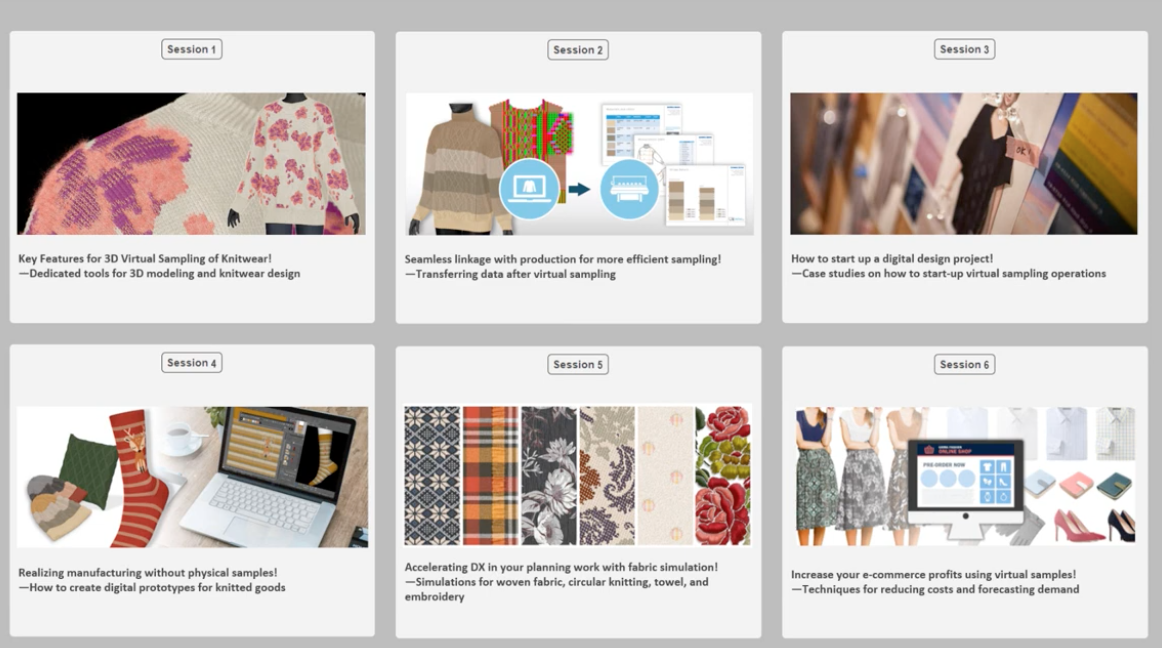

In the final webinar of their series Shima Seiki showcased the potential of their Apex Software to reduce e-commerce imagery costs and forecast demand for online sales.

Demonstrating the tools within Apex which simplify the process and including case studies from brands already utilising Apex for this purpose, Shima shared how to edit and prepare product imagery for e-commerce outputs.

For brands selling online, the shooting and editing of product imagery involves significant financial investment and complex critical path navigation. For products with multiple colour options, each must be shot individually from all angles. This repetitive process means samples are needed in every single iteration of their design, and often these samples cannot then be sold on to consumers. This process is therefore guilty of generating material waste.

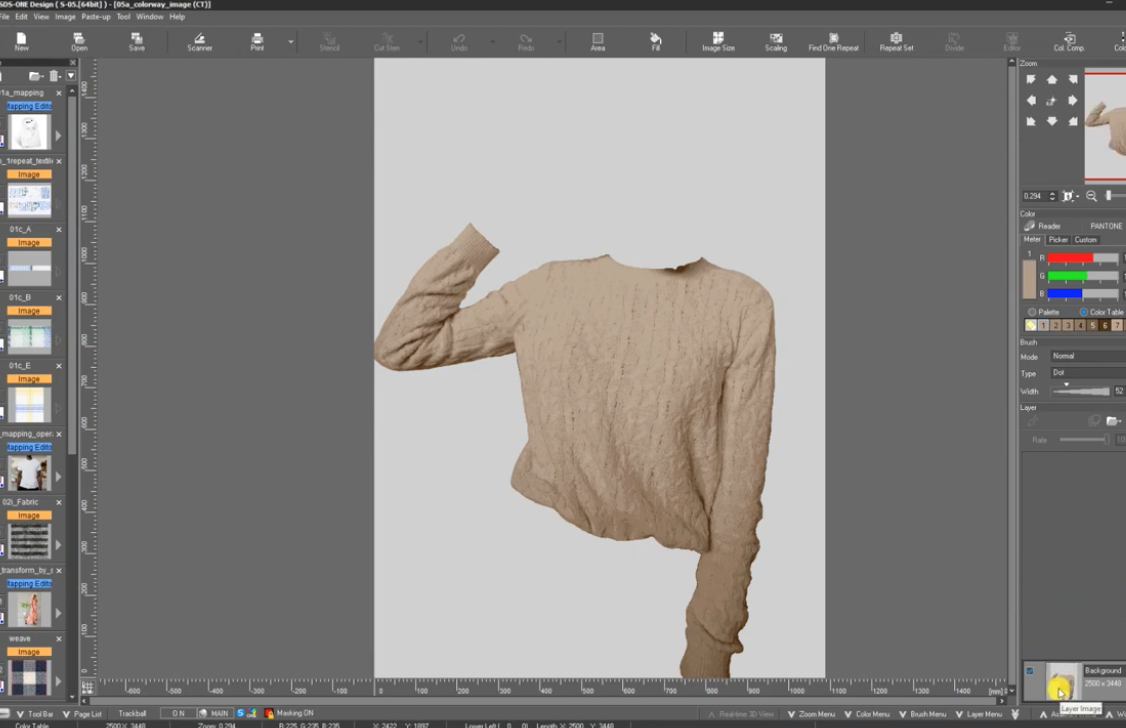

Shima presents a solution to this through their Apex software capabilities. Their virtual samples have benefits over real photos as shoot times can be reduced as well as costs per image. One product can be shot, and within Apex it can be edited. Products can be displayed online without ever having been made or photographed.

Sample costs and material waste have the potential to be reduced here. Of course, this could not be the case for absolutely every product, but within their webinar Shima Seiki showcased some convincing examples of how profits could be increased and lead times reduced using Apex tools.

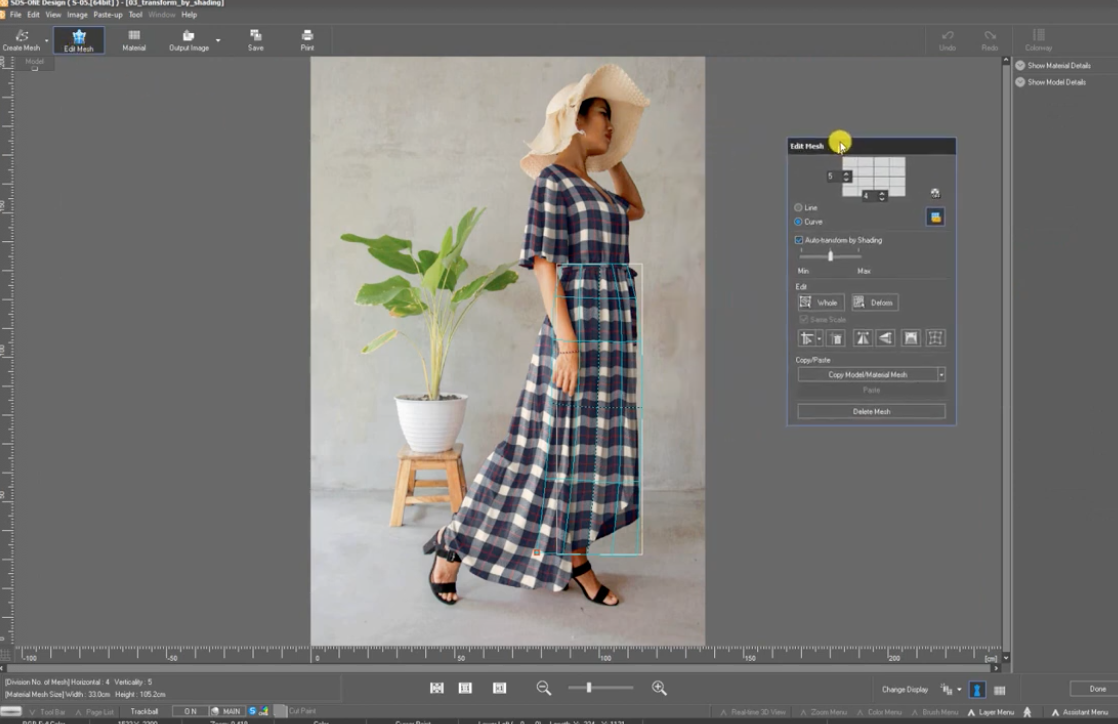

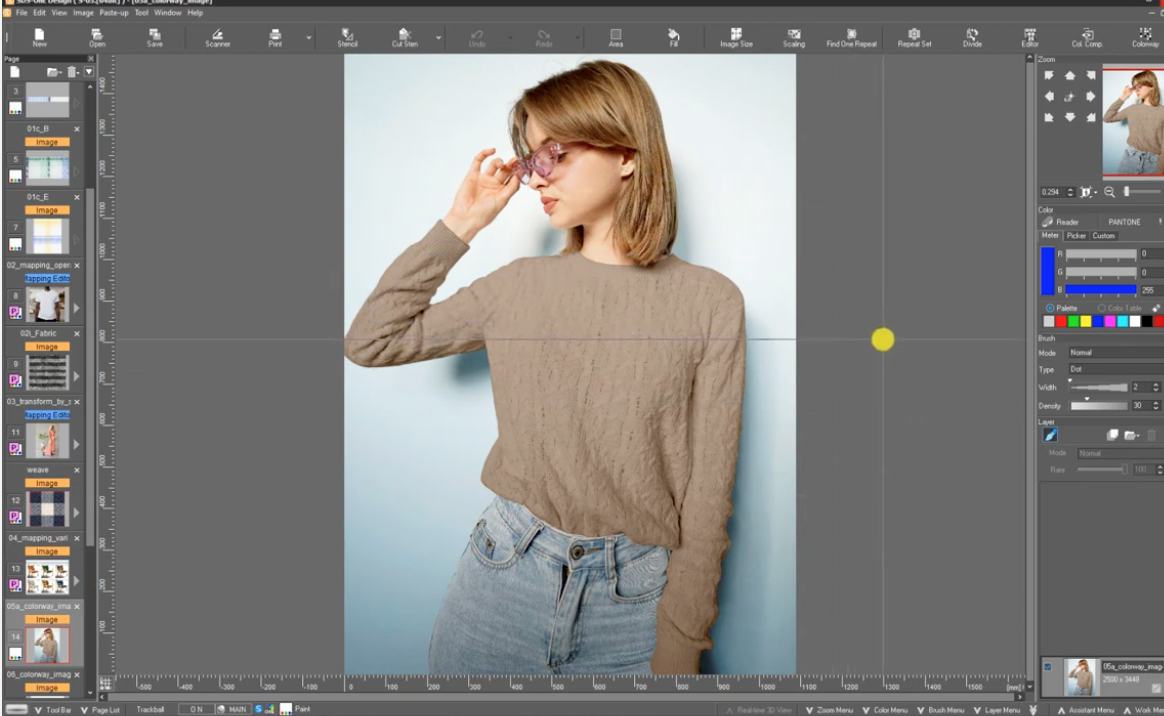

Product photos and fabric images can be combined to make realistic images that show textures, colours and drapes. All the while, shadows and drapes of fabrics are preserved to create highly convincing product options without actually having to produce the products themselves. As long as the user has a photograph of the product they intend to edit along with a photo or scanned image of the fabric they want to use, they have everything they need to create their e-commerce images.

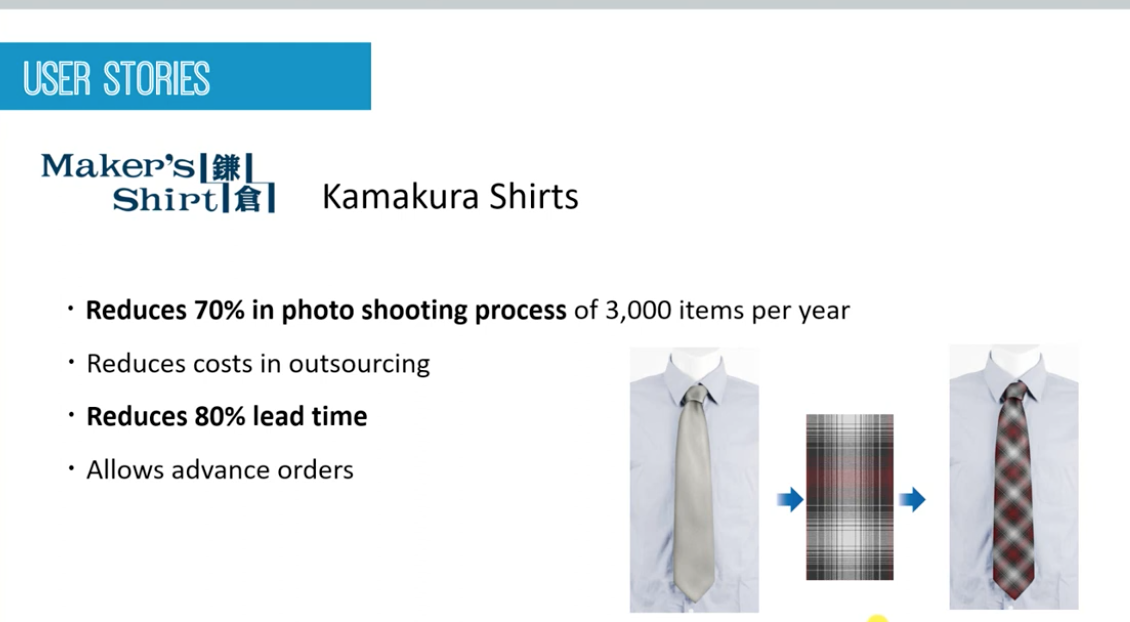

Mamakura Shirts is a company who have been working in this way using Apex. They have reduced photoshoot processes by 70% and reduced costs of outsourcing too, whilst also reducing lead time by 80%.

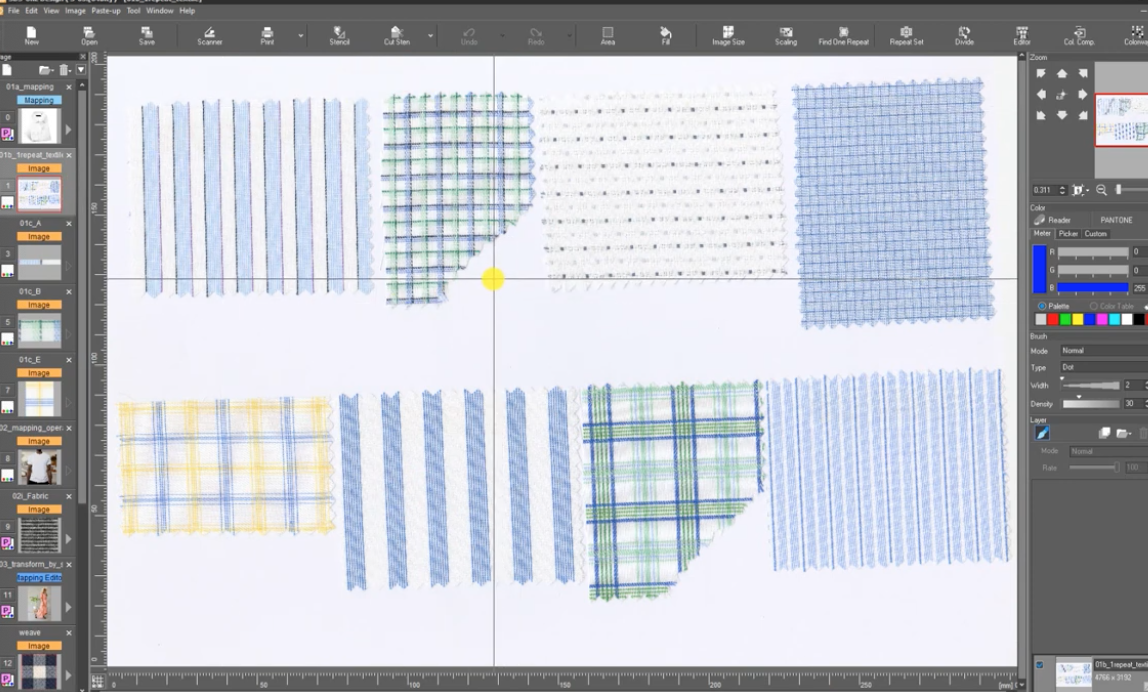

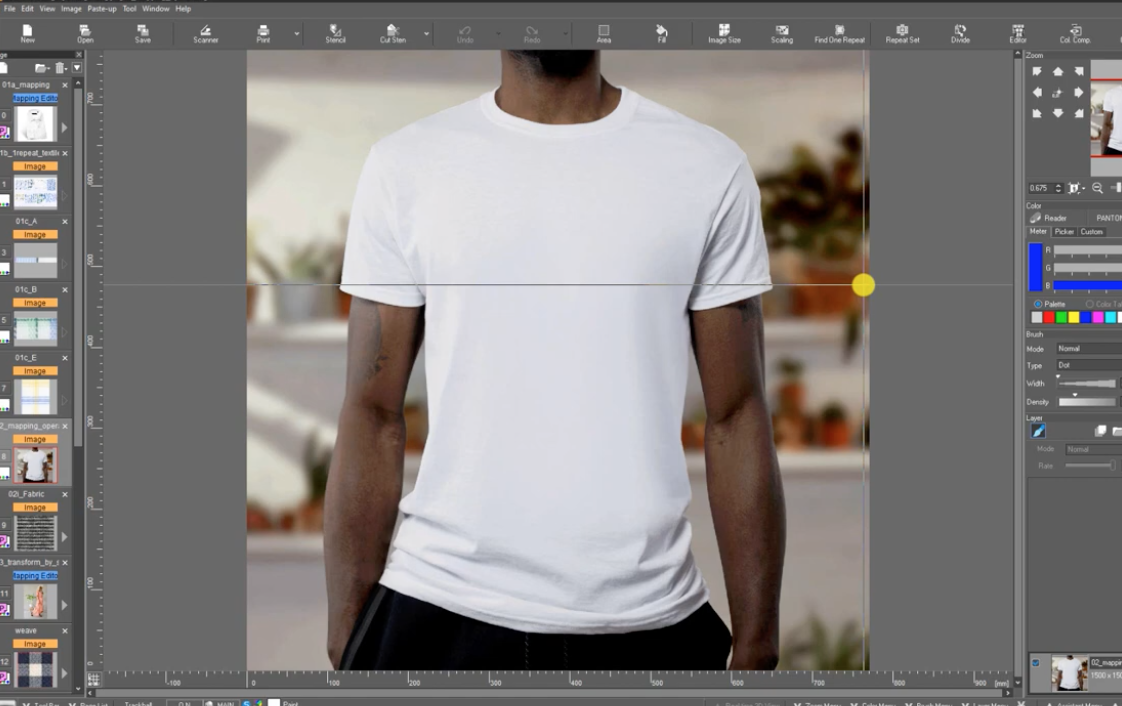

Editing fabrics on product images

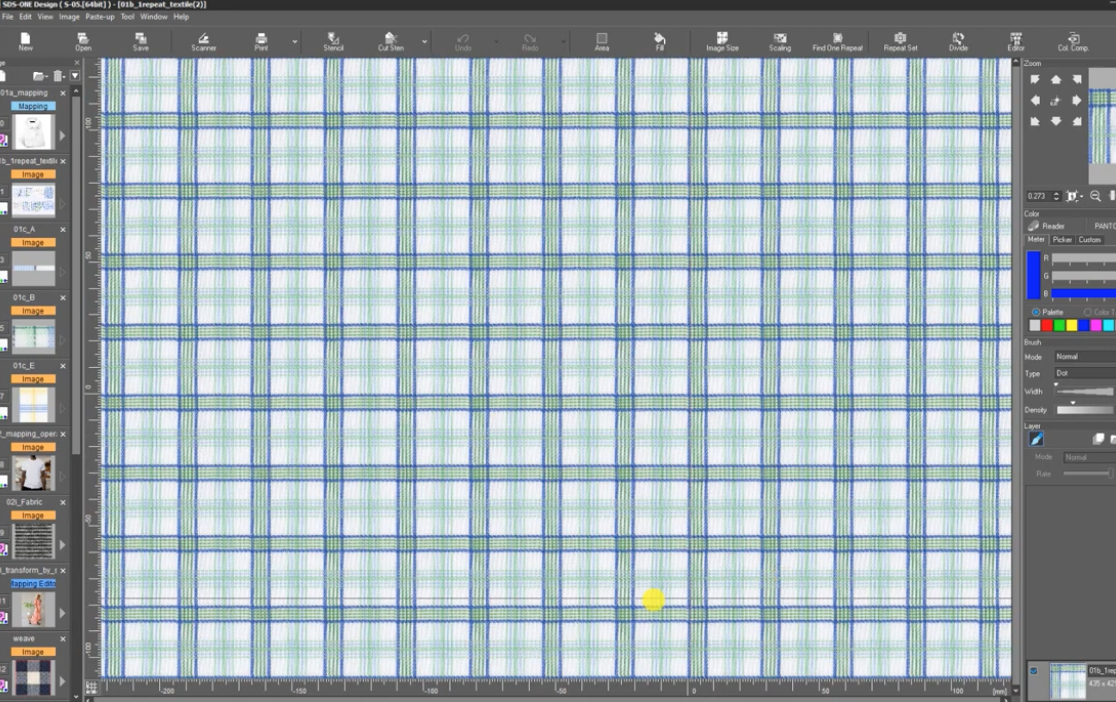

Two types of data are needed to begin- a photo of the product and a photo of the fabric to impose onto it. Often designers only have small swatches of fabrics from mills, but this is no problem. Apex can create repeat patterns from even the smallest samples. A highlight of this function is that it corrects any distortions and misalignments in the way fabrics have been scanned in too. If a tartan fabric was scanned in on a diagonal, the software can auto align it and create a repeat. Seemingly small details such as this combine to save users a significant amount of time in the imagery preparation process.

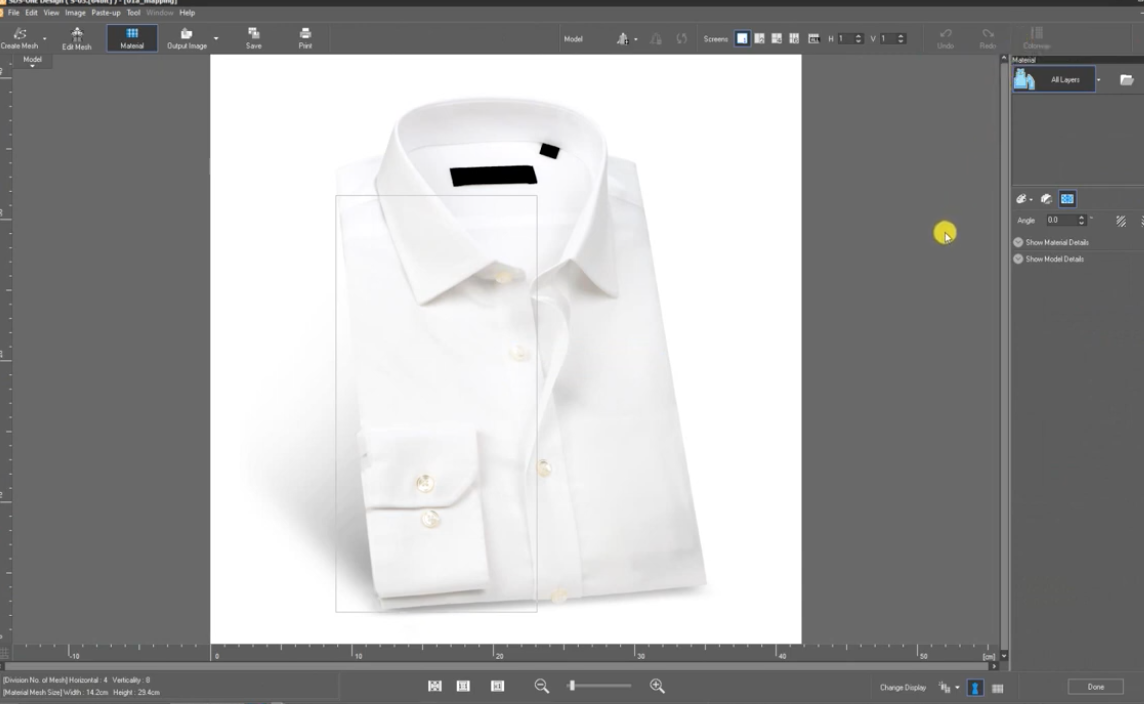

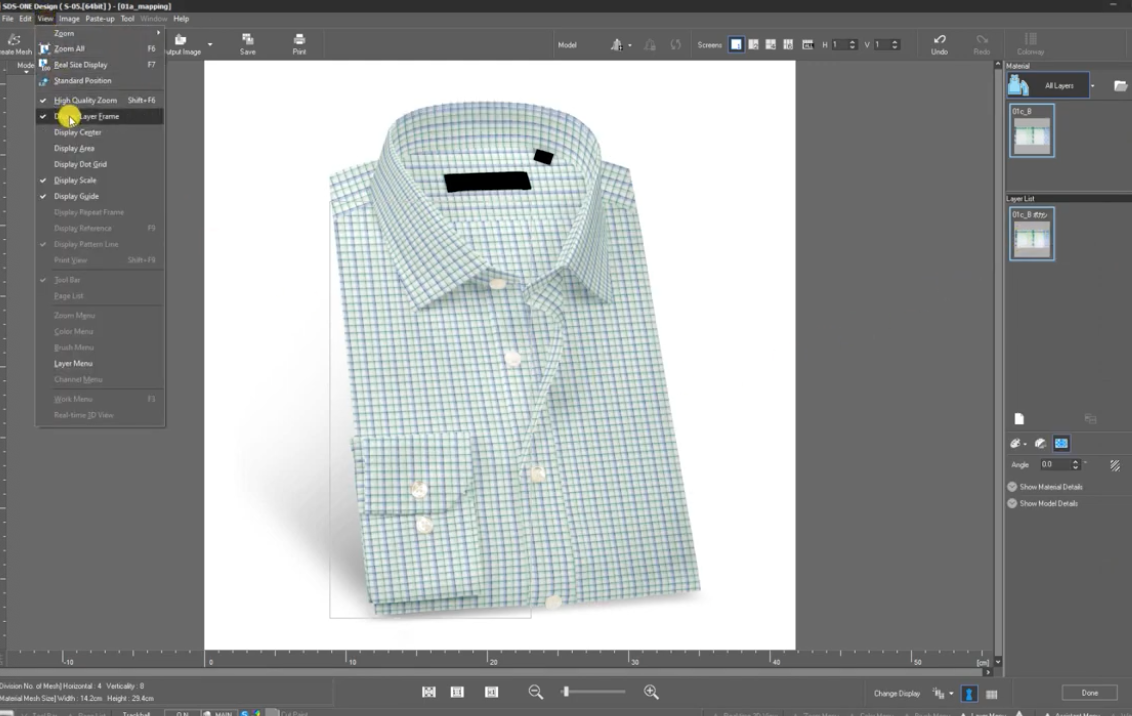

Once the fabric data is ready, it can be combined into the product image using the mapping editor function. Users can select the fabric they want to combine with the product data, and it will be imposed onto the product. The texture and 3D effect of the fabric are realistically expressed and, crucially, the natural shade and shadowing of the product are maintained. More time is saved here as there is no need to add shadowing manually to garment folds and drape lines.

Shima advised that the key to successful product edits lies in the preparation of the original product image. Products with plainer fabrics often work best in terms of simplicity of process (though patterned images can be prepared and edited too with a little more work). Their advice to avoid black products where possible made sense, as within black products the shading is often lost resulting in loss of 3D impact.

Once completed, edited images can be saved in a variety of settings and formats to ensure suitable outputs for e-commerce use.

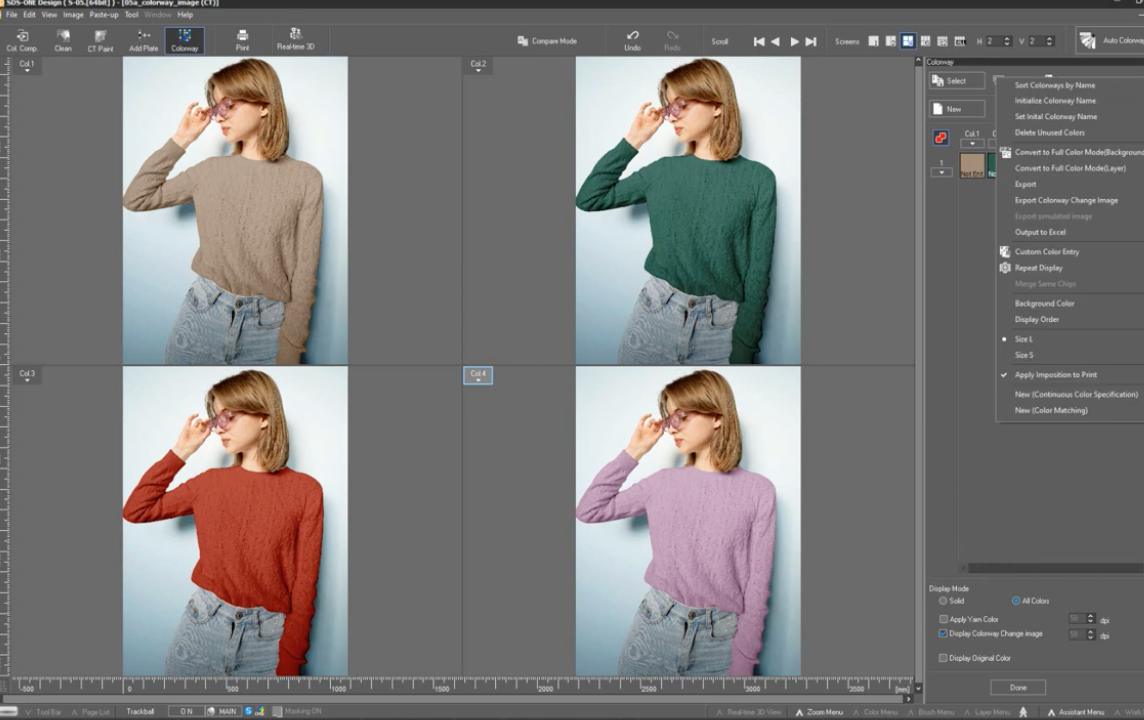

Colour way function

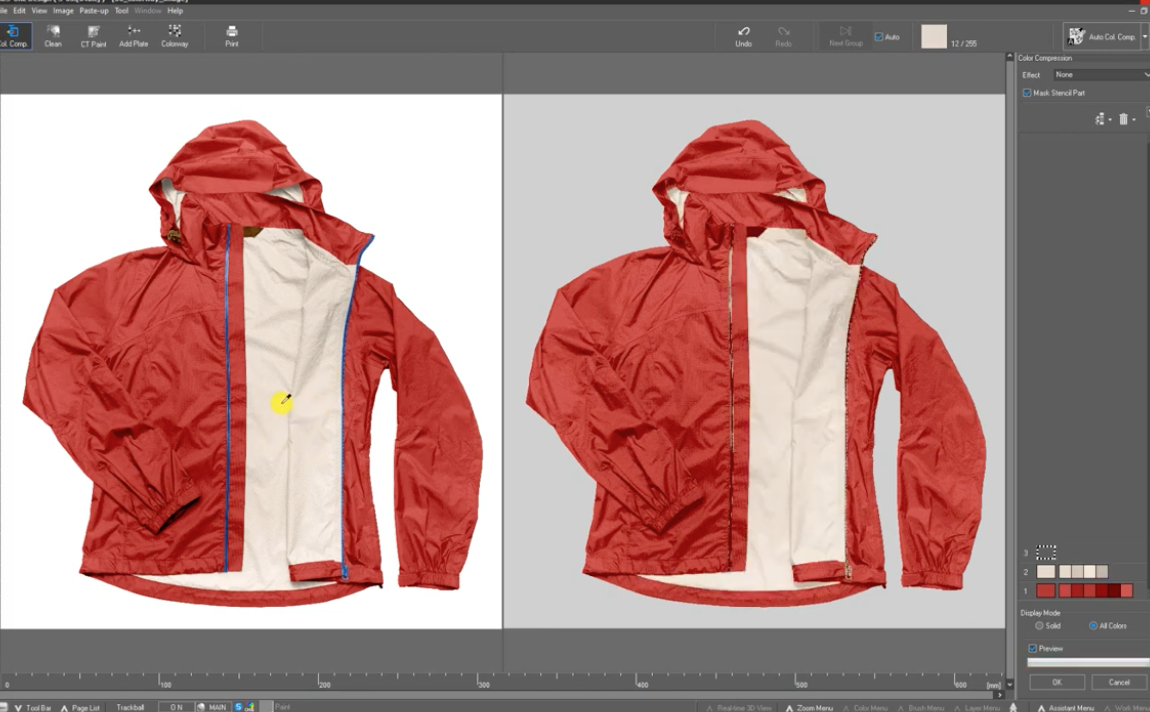

As well as imposing fabrics onto products, Apex can simply change the colours of products too. First users must specify the area of the product within the image they are using, selecting only the part to be recoloured. The automatic stencil setting accurately outlines the product, and paint mode allows users to adjust any areas which may have gone ‘outside the lines’. By inverting the stencilled area once completed, the background is then blanked out, allowing Apex to focus on just the product area to re colour.

Colour registration is the next stage. Users must open the colour compression tool and drag the curser over the item to pick out the colours. As the curser is dragged over new colours, each colour will appear on the lower right corner of the screen.

To change the existing colour, the colour way menu is opened. To create new colours, users click on ‘new’ and then select from the colour chips/ hue range. As with fabric imposing, the shading and texture of the product is preserved- partly what contributes to the realistic outcomes. This simple and realistic colour way editing process holds the potential to reduce sampling photoshoot costs, as products in multiple colour ways can be easily edited and presented online to consumers accurately.

For products with more than one colour such as the coat used to demonstrate during the webinar, colours can be edited individually. Using the colour compression tool as previously, this time users drag the curser only over the single colour they want to copy. For example, a red coat with a cream lining would need to be compressed first as just the red outer, then just the cream lining.

This allows Apex to identify the colour ‘areas’ it will then edit later. Each different colour can be registered as separate colour groups displayed on the bottom right corner of the screen. This process can be repeated for however many colours there are. Trims such as zips can all be registered as different colour groups, so editing can be highly refined without the need for the often fiddly area selection tools of other software.

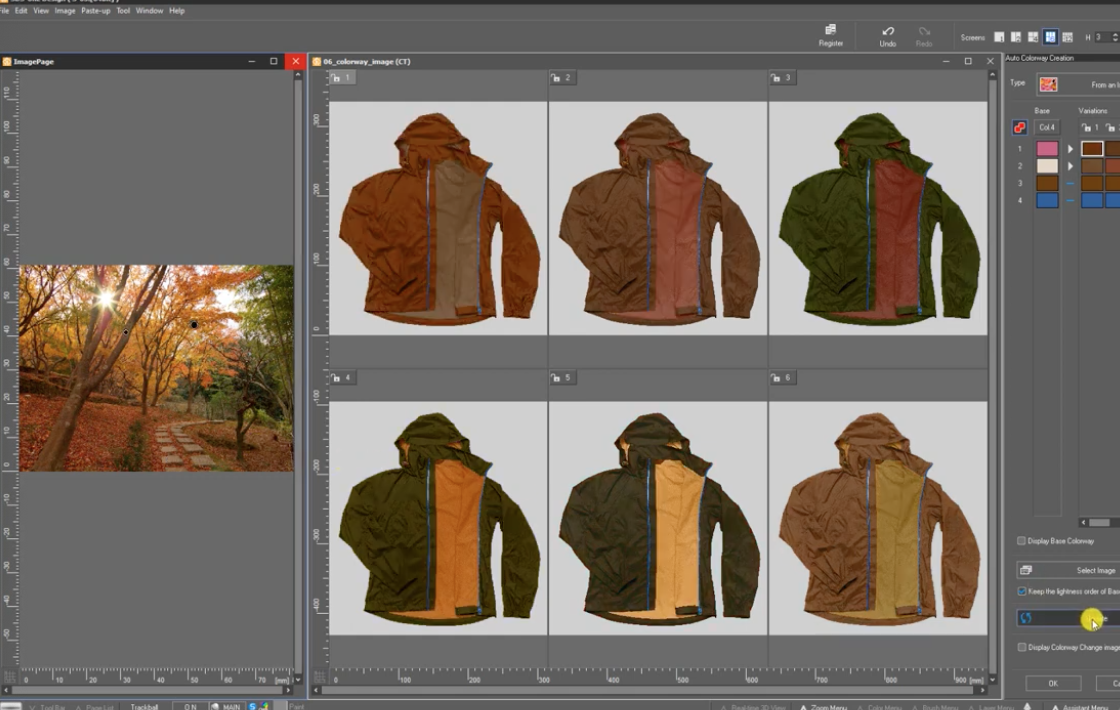

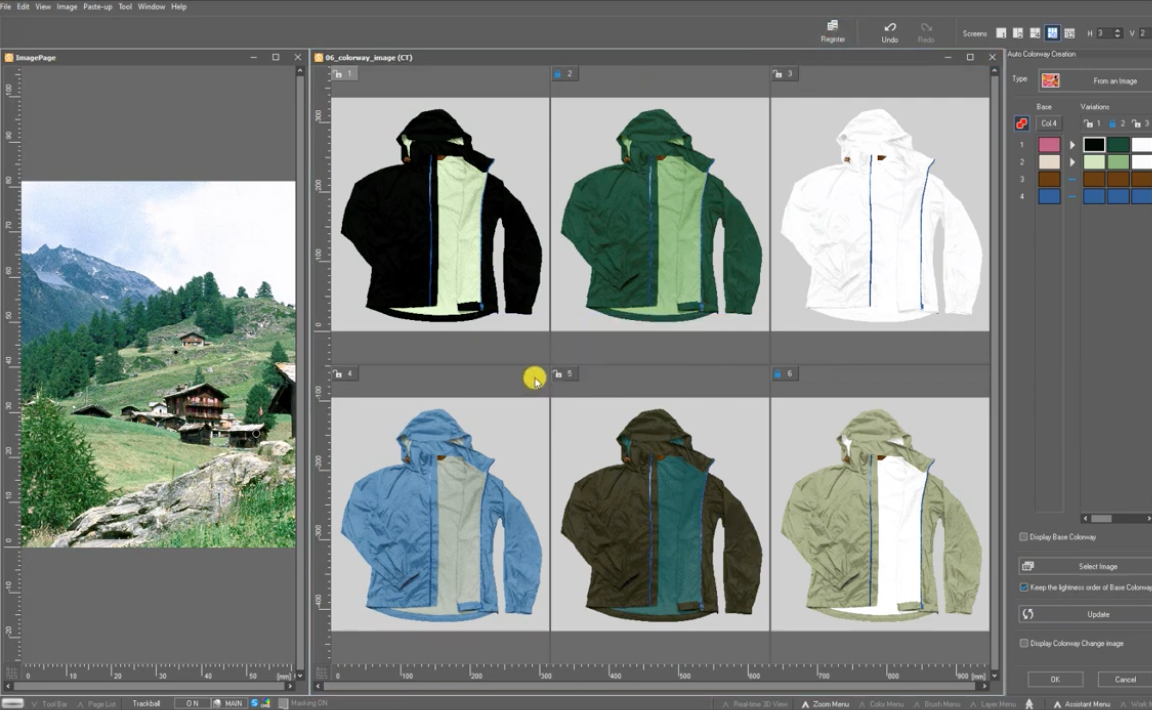

Apex can also auto generate colour palette variations to select from. From a product development perspective this has the potential to save a lot of time by cutting out the need to manually colour up numerous cads for each product.

For users with a specific trend or brief in mind, colour boards can be imported and Apex can create colourway variations based on these.

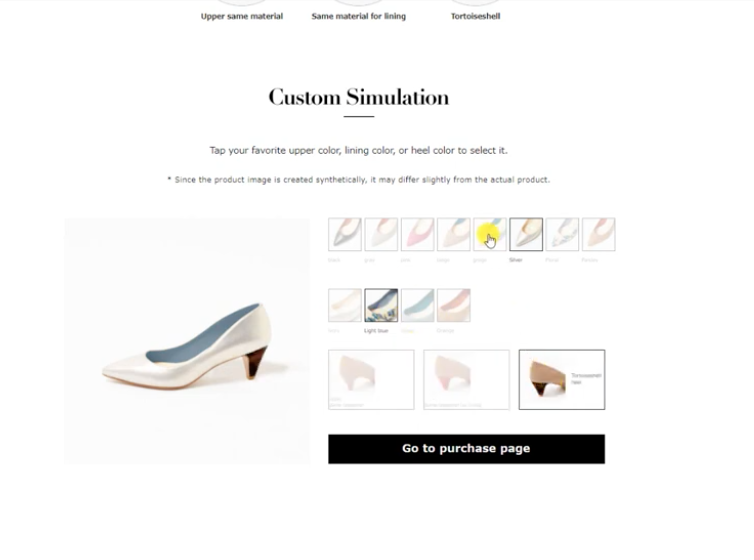

Potential within custom made markets

For companies offering customisation options within e-commerce platforms, shooting products in the various iterations of their possibilities can be costly and time consuming. For smaller businesses working on bespoke products, this can result in lower profits.

Within this context, Apex has the potential to save companies time and expenses by enabling them to shoot just one product and create the customisable options through their image editing processes. Though of course it cannot be denied that there will be some products for which this process will work more convincingly than for others.

Could this help brands to forecast their buys?

Particularly within the fashion industry, buying teams must make well informed predictions about which products and colours will have the best sales performances. Shima suggest their software has the potential to intervene in current buying processes by allowing companies to gain pre-order information before placing product orders with factories and investing in raw materials.

Of course, this would need some serious navigating in terms of meeting the turn-around times for factories to then deliver the pre ordered goods. But it is certainly ‘food for thought’. There is also a danger that if the final product does not match the edited image, customers could be dissatisfied. But, if employed with attention to detail, this could become a method of selling within e-commerce that saves material waste.

This webinar marked the end of this series of online presentations from Shima Seiki. Providing a thorough overview of the many attributes of Apex, Shima proved their software has potential across a variety of industries to ‘shake up’ current supply chain and e-commerce channels.

Apex has a lot to offer to brands who are quite rightly under so much pressure to reduce their environmental footprints. Caution must be exercised in relation to Apex’s ability to cut lead-times however. Fast fashion brands with agendas of trend driven fast turn arounds could manipulate this to ensure they can make even more, even quicker. Apex cannot be used as a tool to fuel fast fashion, it must be used to reduce material waste and improve communication between designers and suppliers. If this balance can be achieved then Shima Seiki’s Apex software certainly offers exciting options to our evolving industry.

Subscribe To Our Newsletter

Join our mailing list to receive the latest news and updates from our team.