Since 1960, Filati Be.Mi.Va has presented yarns both technical and fancy to the industry. Sourcing raw materials from around the globe and creating its yarns in Italy, Be.Mi.Va’s ethos values its tradition as an opportunity for safe, responsible growth for new generations rather than a restraint on development. This commitment to its roots as a generator for innovation was perhaps an instigator for its explorations into sustainability.

In February 2016 Be.Mi.Va signed the Detox Commitment promoted by Greenpeace; its Summer 2020 L.E.A.F. Collection is an embodiment of its commitment to this initiative.

During Pitti Filati in January 2019, the L.E.A.F Collection of viscose, lyocell and polyamide from a variety of sustainable sources was revealed. This collection is an exciting addition to the repertoire of any designer looking to work towards ‘Cradle to Cradle’ standards, reduce waste, and increase traceability within collections.

Be.Mi.Va’s Interseason yarns focus on springtime with wool crepe and celebrate cottons and viscose for transitional, wearable garments. Its Summer offering is frequently a realm of fine count viscose, crisp hemp and purposefully imperfect slub linens. Not the first spinner to take this approach, Be.Mi.Va is now offering L.E.A.F alongside its core collections.

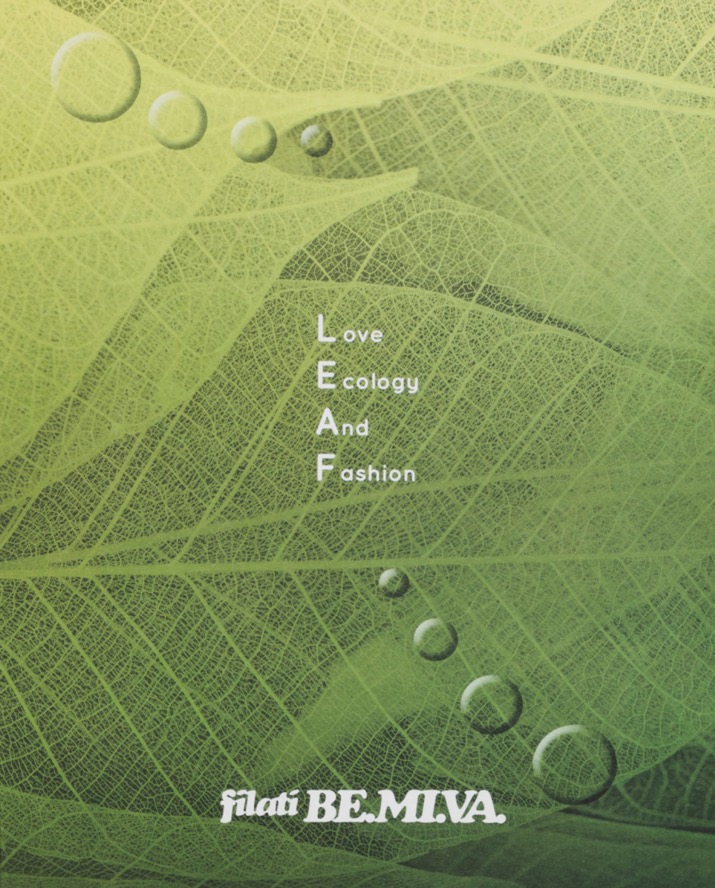

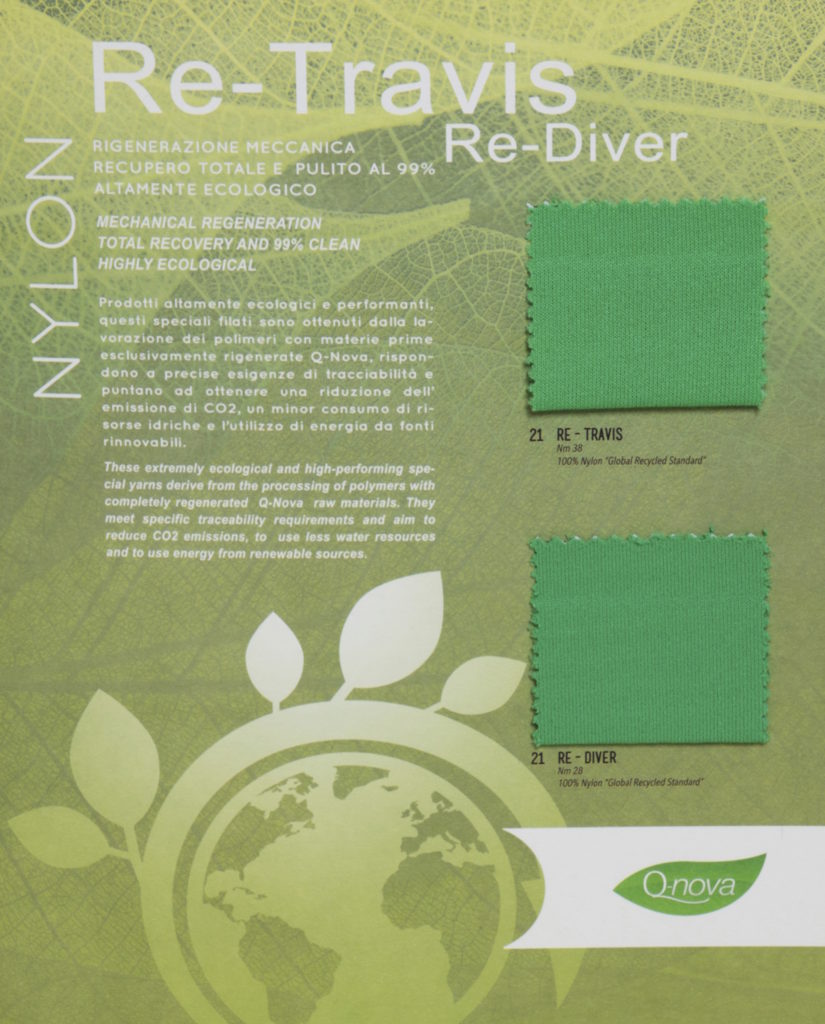

Some of L.E.A.F’s yarns are mirrored within the main seasonal collections, but are presented as sustainable alternatives – like a sister yarn to the core collection: this is an intriguing concept. It offers seamless transitions to yarns with the same handle, aesthetic and characteristics but with less environmental impact. Its Re-Diver nylon is an example of this.

Nylon

Be.Mi.Va’s Re-Diver is a sustainable alternative to its Diver yarn. Both yarns are 100% nylon, but the new Re-Diver is 100% Global Recycled Standard. Re-Diver is derived from the processing of polymers using Q-Nova technology. Q-Nova by Fulgar is a nylon created from regenerated raw materials which meets traceability standards. Re-Diver nylon can biodegrade within a few years as opposed to centuries. This is a positive step toward ‘Cradle to Cradle’ design.

Holding a swatch of Diver in one hand and Re-Diver in the other, any obvious differences in handle are indistinguishable. Re-Diver holds the potential for a subtly less consistent colour application, but plying is suggested to resolve this issue – a method often used in any event. In time as the process evolves this could be remedied.

If produced in an identical count to Diver, it would be inspiring to see Re-Diver become a permanent replacement within the collection. Developments such as this could make it easier for brands to implement responsible material sourcing decisions.

Lyocel

Using the Refibra recovery system by Lenzing, Be.Mi.Va has created Eco-8. By upcycling cotton waste, yarn waste and pre-consumer fabrics, Tencel Lyocell fibre is created. Mixed with 18% polyester, further development of Eco-8 is required to achieve 100% biodegradability. Nevertheless the high percentage of recycled material content represents a positive example of alternative waste management. It constitutes a proactive approach to reducing landfill waste.

Each yarn within L.E.A.F approaches material waste reduction in a different way. This captures the essence of the challenge facing sustainable design. There is no standard formula to sourcing different fibres responsibly. A multi faceted approach is required to adapt to the individual requirements of each material and manufacturing process.

Micromodal + Viscose

With over 80% of species living in rain forests, it is vital that these environments be protected. L.E.A.F supports the responsible foresting of textile fibres.

“Lenzing EcoVero viscose and micromodal stable fibres have been created for a sustainable and modern lifestyle, contributing to a cleaner environments.”

Be.Mi.Va SS20

‘Intimo’ viscose and ‘Nude’ micromodal are made from cellulose from certified plantations where sustainable practices are in place. Be.Mi.Va’s FSC certified Micromodal and Viscose Fiocco Lenzing EcoVero yarns are respectful of forests, with lower emission and water consumption than their equivalents. Spinners such as ENKA have been treating forests respectfully and endorsed by brands such as Stella McCartney for some time.

By further expanding the market, Be.Mi.Va is contributing to the ever-expanding industry palette of sustainable yarns for designers.

Progress for Brands

With brands such as Stella McCartney endorsing the ReVerso approach, Filpucci, and high street brand Whistles following suit with its own ReVerso Cashmere capsule collection, it is clear that across market levels interest in sustainably regenerated fibres is on the rise. Whistles said of its Reverso Collection:

“The launch of the ReVerso cashmere collection is the start of our commitment to explore substitutions of key raw materials that carry transparency, circularity and sustainable sourcing as their main attributes, without compromising on style and quality.”

L.E.A.F caters to this widening market, offering yarns for summer garments. Filpucci’s cashmere has been accepted and developed, and the story of its yarn has been valued by Whistles and Stella McCartney. The narrative stored within each L.E.A.F yarn could certainly be endorsed in the same way by designers, and utilised to encourage informed purchasing habits within consumers.

Future Potential

Sustainable fibres are the future, and traceability is fast becoming a demand of Millennials and Generation Z. As well as the numerous emerging spinners and start-ups presenting entirely sustainable collections, it is crucial that those spinners with the reputations and funding endorse the values of sustainability and lead the challenge of cleaning up their collections.

Arguably, by focussing on L.E.A.F, Be.Mi.Va is ironically becoming its own competition in certain respects. In the event designers purchase Re-Diver, Diver sales will fall. But a brand that is setting up an infrastructure to cater to a wider market of sustainable designers will be ready to switch to these production methods as industry demands. If spinners like Be.Mi.Va can create more sustainable direct alternatives to their own yarns, they could be substituted in like for like. Brands willing to adapt to market demands and become instigators of change are the future.

The perceived restrictions of sustainable practice can deter designers from taking on the challenge. With deadlines, sales pressures, and marketing strategies contributing to design processes, sustainability can present as an obstacle.

If Industry recognised spinners can provide a variety of enticing sustainable options to designers, balancing desirability with sustainability will become the established norm. The progression of L.E.A.F and Be.Mi.Va’s continued commitment to sustainable design is certainly a journey to watch.

Subscribe To Our Newsletter

Join our mailing list to receive the latest news and updates from our team.