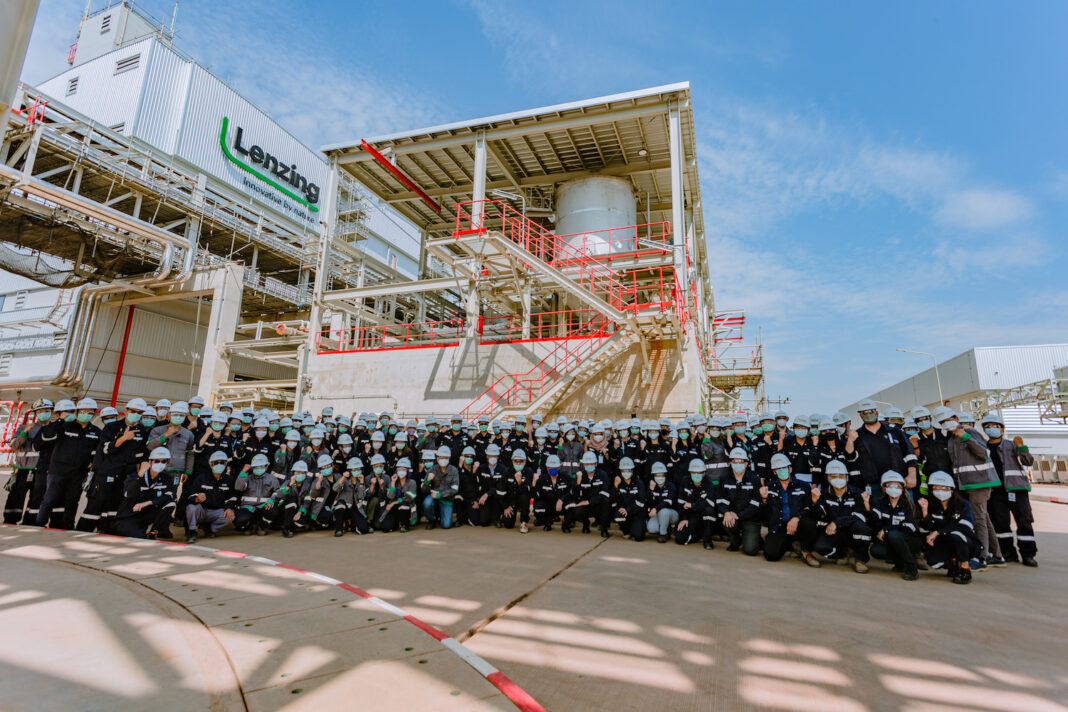

Prachinburi, Thailand

Project delivered on schedule and at budget after two and a half years of construction despite challenges arising from a global pandemic.

The Lenzing Group, the world’s leading supplier of wood-based specialty fibres, is pleased to announce the successful completion of its key lyocell expansion project in Thailand. The new plant, the largest of its kind in the world with a nameplate capacity of 100,000 tons per year, started production on schedule and will help to even better meet the increasing customer demand for Tencel branded lyocell fibres.

For Lenzing, the project also represents an important step towards strengthening its leadership position in the specialty fibre market and into a carbon-free future.

The construction of the plant located at Industrial Park 304 in Prachinburi, around 150 kilometres northeast of Bangkok, started in the second half of 2019 and proceeded largely according to plan, despite the challenges arising from the COVID-19 pandemic. The recruiting and onboarding of new employees has been successful. Investments amounted to approxi,ately EUR 400 million.

“We are very proud of this achievement. Our sincere thanks go to the entire Lenzing team and especially to our staff in Thailand but also to many external stakeholders, who joined forces in times of a global pandemic to make this key project reality. To deliver such a huge project in time and at budget is an outstanding achievement given the challenges of the global pandemic”, said Cord Prinzhorn, CEO of Lenzing Group.

Robert van de Kerkhof, Member of the Managing Board, agreed with him and added: “The demand for our wood- based, biodegradable specialty fibers under the Tencel, Lenzing Ecovero and Veocel brands is growing very well. In Asia in particular, we see huge growth potential for our brands based on sustainable innovation. With the production start of the lyocell plant in Thailand, Lenzing reached an important milestone in its growth journey, supporting our ambitious goal to make the textile and nonwoven industries more sustainable.”

Worldwide expansion of lyocell production

The lyocell production process is the most modern method for producing fibres from wood. It has been successfully applied on an industrial scale for about 30 years and is particularly environmentally responsible. The underlying idea of the lyocell process is to dissolve and process the pulp in a closed loop without any chemical derivatisation.

Lenzing will continue to expand its production capacity for lyocell fibres in line with its sCore TEN strategy, which aims to generate 75% of its fibre revenue from eco-responsible specialty fibres such as Tencel, Lenzing Ecovero and Veocel fibres by 2024. The Thailand site offers space for several production lines. The investment in the first phase already includes general infrastructure that would benefit future expansion. However, Lenzing will also continue to look for opportunities to expand lyocell production in other parts of the world.

Vision of a zero-carbon future

“Investments in Thailand and other Lenzing sites around the world support us not only along our transformation towards becoming a supplier of eco-friendly specialty fibres but also in implementing our ambitious climate tar- gets, thus further increasing our company value”, said Cord Prinzhorn.

In 2019, Lenzing made a strategic commitment to reducing its greenhouse gas emissions per ton of product by 50 percent by 2030. The vision is to be climate-neutral by 2050. Due to the established infrastructure, the site in Thailand can be supplied with sustainable biogenic energy and contribute significantly to climate protection.

Together with the key project in Brazil and the substantial investments at the existing sites in Asia, Lenzing is currently implementing the largest investment program in its corporate history (with more than approx. EUR 1.5 billion). Lenzing will continue to drive the execution of its strategic projects, which are to make a significant contribution to earnings from 2022.

Subscribe To Our Newsletter

Join our mailing list to receive the latest news and updates from our team.