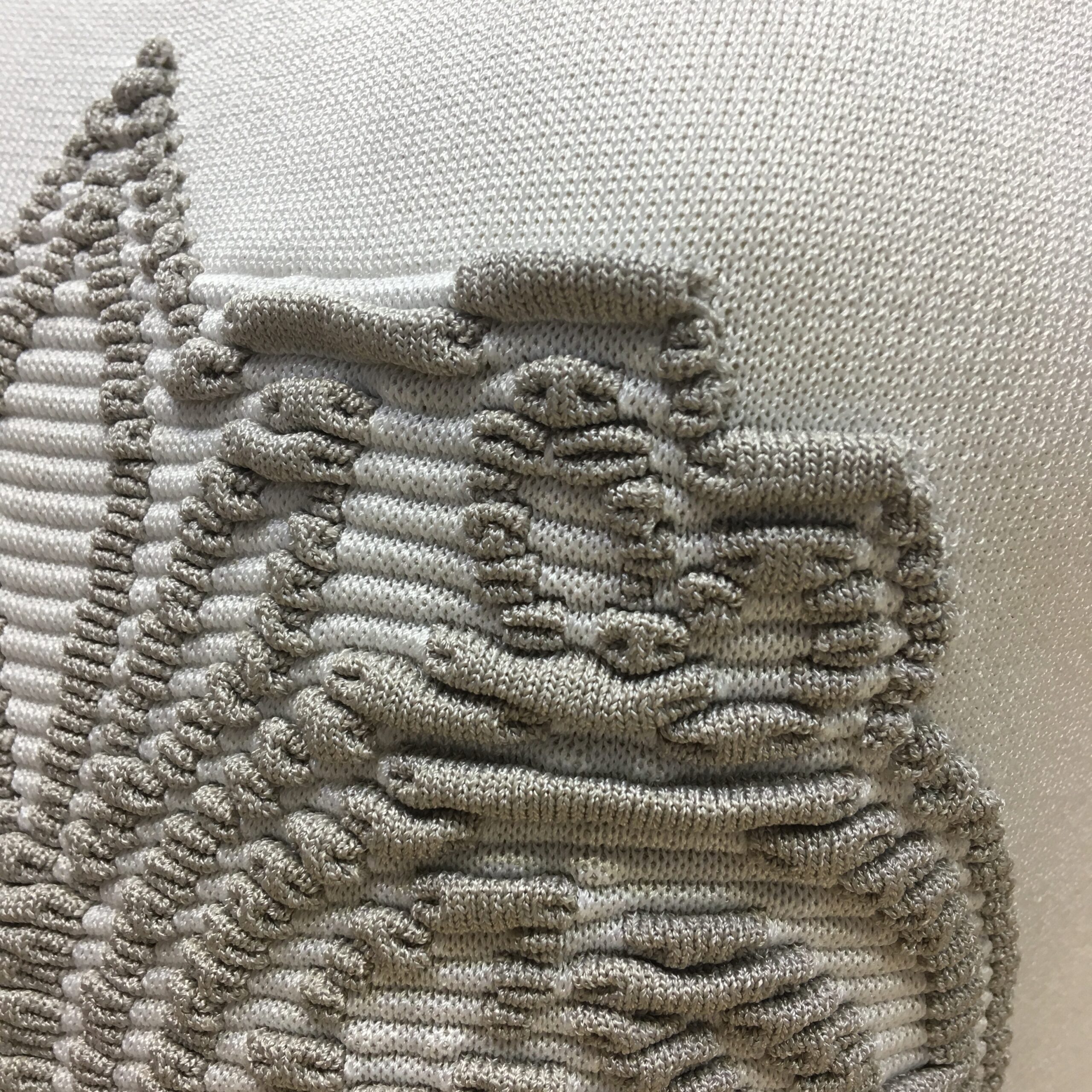

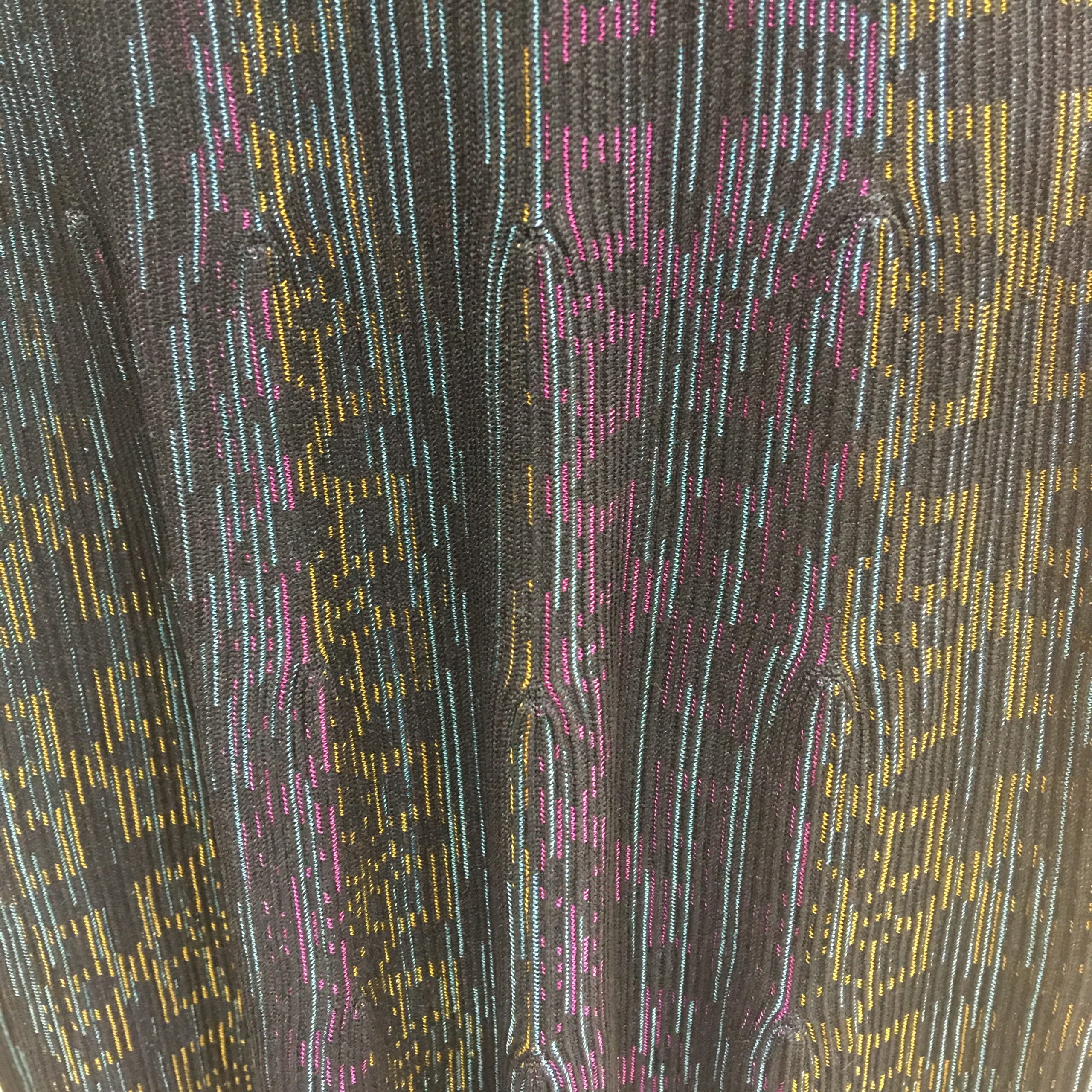

In addition to eight next-generation flat knitting machines, more than 300 items were on display for knitted applications ranging from fashion to industrial textiles.

Leading flat knitting technology company Shima Seiki participated in the International Textile Machinery Association exhibition (ITMA 2023) in Milan, Italy, from 8-14th June. The pioneering Japanese company’s unswerving tradition of introducing new technology at ITMA under its guiding philosophy ‘Ever Onward’ remained intact in Milan, with a brand-new line up consisting of new machines and next generation prototypes.

“The next generation group of machines is represented by the letter ‘R’ which stands for ‘Reborn’ and is also the basis for Shima Seiki’s exhibition concept – Shima Seiki Reborn,” Shima’s head of marketing and communications, Masaki Karasuno told Knitting Industry.

Return to origin

Shima Seiki Reborn represents a return to origin, for the company and for its products, and a renewal of passion and commitment toward innovation. At the same time, it represents a renewal of Shima Seiki’s commitment to its customers, the industry and the environment, as all aspects of each machine were re-evaluated in terms of its purpose, the way it is manufactured, how it is used and how it impacts the environment.

“That renewal has been applied to the company’s entire product line-up from WHOLEGARMENT knitting machines to shaping machines, glove knitting machines, and even computerised cutting machines, have undergone complete re-evaluation,” Mr. Karasuno said.

Of the 9 knitting machines Shima exhibited at its 600 square metre booth, 8 machines were part of the next-generation line-up. More than 300 items were on display as proposals for knitted applications in various fields ranging from fashion, sports, shoes, bags and accessories to medical, safety, automotive, aeronautical and other wearable and industrial textile applications.

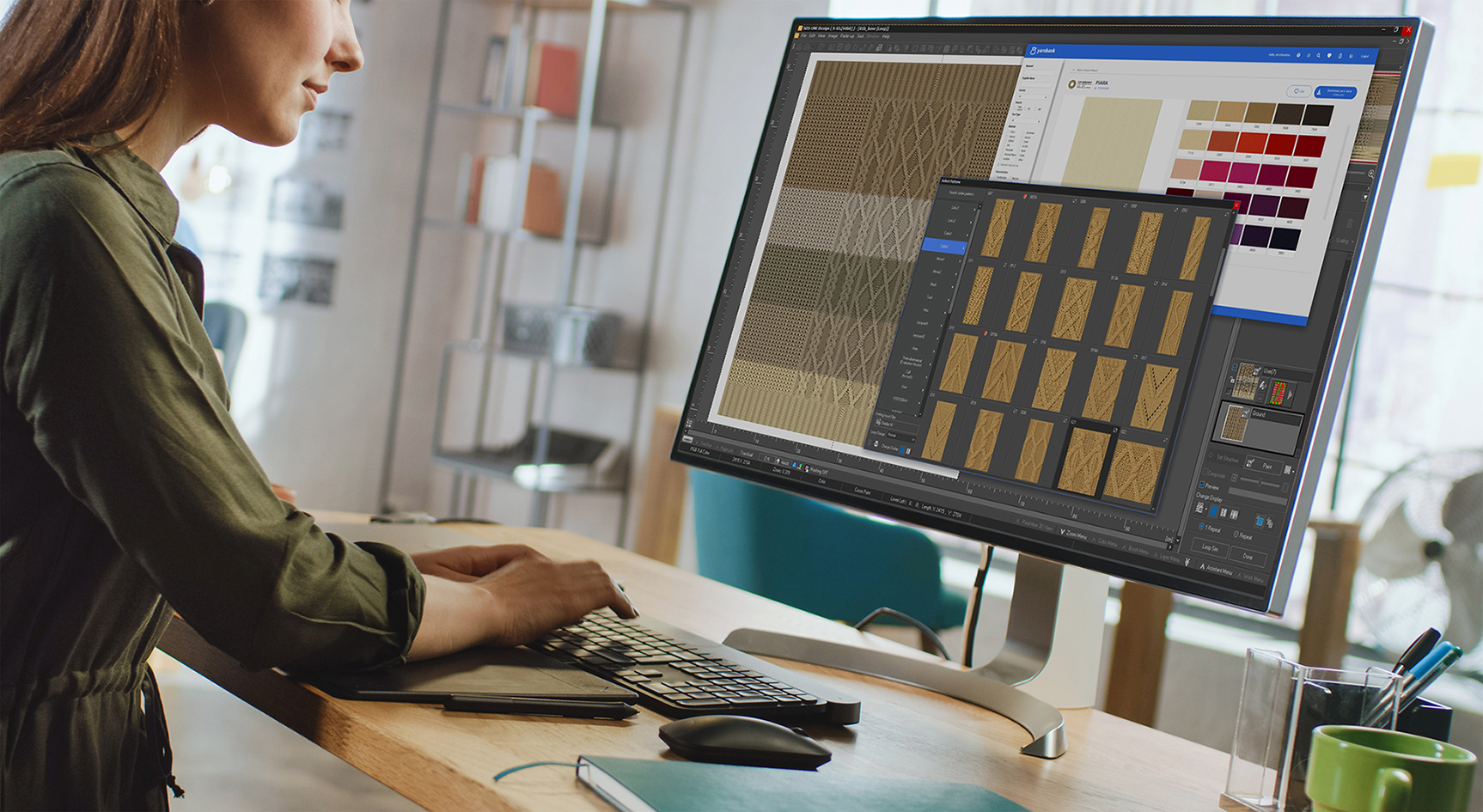

In addition to machine technology, Shima Seiki’s computer graphic design system and software were shown with their latest software upgrades that featured significant improvements in knit programming, 3D functions and speed. Demonstrations were available for a comprehensive fashion tech solutions package based on realistic virtual sampling and supported by various digital solutions and web services.

Back to the future

“There was a time when ITMA exhibitors were required to show only new technology,” Masakai Karasuno explained. “With a revamped line-up and comprehensive display of our latest products and services, visitors to the Shima Seiki booth can once again feel the excitement of seeing a booth filled with new machines exhibited for the first time.”

Next-generation R-series machines

Re-evaluated from the ground up, the R-series machines have been revamped across its entire line-up, from WHOLEGARMENT knitting machines and shaping machines to glove knitting machines, resetting the standard for computerised knitting across the board. Each machine is also a testbed for new features, awaiting feedback from visitors at ITMA. Even the iconic Shima Seiki gold machine livery gives way to a really cool contemporary grey.

For full details of Shima’s ITMA 2023 machine exhibit, please read our Shima Seiki is Reborn at ITMA 2023 article on our Knitting Industry site.

SDS-ONE APEX4 and APEXFiz

SDS-ONE APEX4 3D apparel design system and APEXFiz subscription-based design software support the creative side of fashion from planning and design to colourway evaluation, realistic fabric simulation and 3D virtual sampling. Virtual samples are a digitised version of sample making that are accurate enough to be used effectively as prototypes, replacing physical sampling and consequently reducing time, cost and material that otherwise go to waste.

When a design is approved for production, knitting data which is automatically generated can be converted easily to machine data, allowing smooth communication for digitally bridging the gap between design studio and factory.

Before going to production however, the same virtual samples can be used in retail, for example in e-commerce, to gauge consumer response to items before going to market, effectively realizing production based on demand forecasting. In such a way, inventory can be optimized to minimize deadstock waste. SDS-ONE APEX4 and APEXFiz therefore help to realize sustainability while digitally transforming the fashion supply chain.

At ITMA 2023 new software was shown that improves realism for virtual samples even further, as well as new intarsia programming software that reduces lead time significantly. Demonstrations were available in various locations throughout the Shima Seiki booth during ITMA.

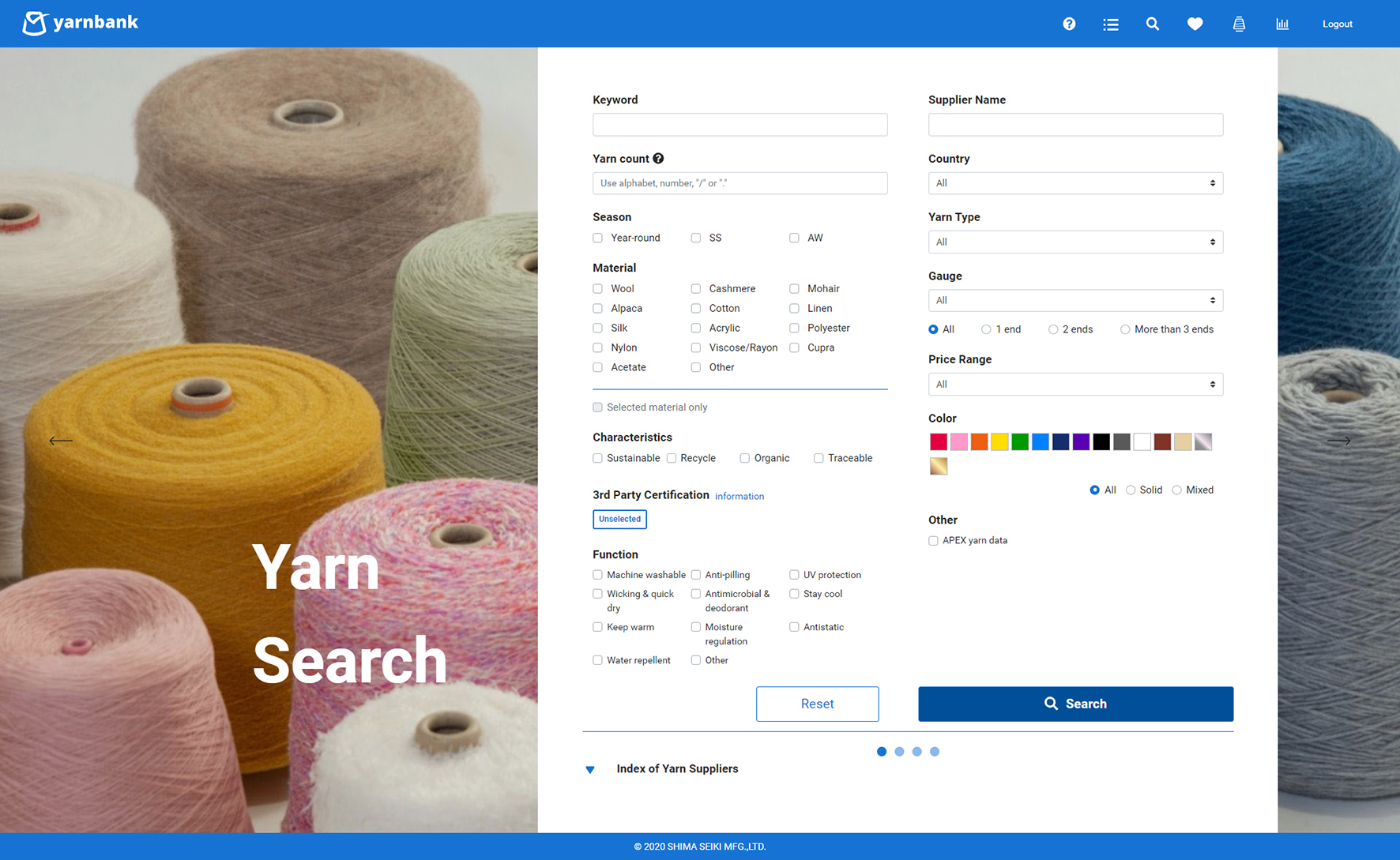

yarnbank

yarnbank digital yarn sourcing web service is the world’s first online service for searching and viewing the latest yarns, developed in cooperation with yarn companies from around the world. Registered users can download yarn data for free, for use in fabric simulation and virtual sampling on SDS-ONE APEX4 and APEXFiz, avoiding the need to scan yarn on their own.

By using yarn that is used in actual production, designers and apparel companies can furthermore rest assured that the simulations created using yarn from yarnbank are not merely realistic images but accurate representations using yarn that can actually be purchased and used in production.

Shima Datamall

The Shima Datamall digital content web service is an online service that allows users to search, browse and purchase a variety of useful data for the planning, production and sales of fashion items. Over 8000 pieces of data, ranging from knit item data and knit design data to 3D model patterns are available.

Users of SDS-ONE APEX4 and APEXFiz Design software as well as Shima Seiki flat knitting machines will be able to streamline their operations and further promote the digital transformation of textile manufacturing, thereby realising a shift toward sustainable manufacturing.

Shima KnitManager

Shima KnitManager is production management software designed for the flat knitting factory and was developed as a solution to rethink the traditional planning and production process of knitwear.

Visual confirmation of various pieces of information such as machine operation status and production progress is available for maximising productivity and eliminating waste.

Online monitoring service allows progress reports to be checked via web application. With abundant experience in the flat knitting industry, Shima Seiki proposes optimal solutions that contribute to customer success regardless of business type, business content or region.

Rebirth

Recovering from the impact of the pandemic, the global textile industry demonstrated remarkable resilience, capturing the world’s attention with its strong presence at ITMA 2023 in Milan. The highly anticipated exhibition served as a comprehensive showcase of cutting-edge technologies, brought to life by an impressive gathering of 1709 exhibitors.

ITMA 2023 attracted decision-making industry leaders and influential entrepreneurs who recognised the exhibition’s significance in shaping the textile industry’s future. ITMA 2023 in fact felt like a bit of a rebirth for the industry – the first event that felt normal. Shima Seiki’s next generation group of machines represented by the letter ‘R’ which stands for Reborn and its exhibition concept – Shima Seiki Reborn, therefore seem all the more relevant.

Subscribe To Our Newsletter

Join our mailing list to receive the latest news and updates from our team.