Lea Mills, Derbyshire, United Kingdom

Celebrating 240 years of the world’s finest knitwear, the strategic initiative aims to encourage brands to bring knitwear manufacturing back to UK shores.

Iconic British knitwear brand John Smedley has announced that its Derbyshire factory is opening for third-party manufacturing. Coinciding with the knitwear company’s 240th birthday, John Smedley will reopen its production lines to brands for seasonal orders.

Working in partnership with The Board of Trade, the British Fashion Council and the UK Fashion and Textiles Association, this strategic initiative by John Smedley aims to encourage brands to bring knitwear manufacturing back to UK shores.

By boosting the factory’s output, it will also futureproof the company and proudly support local jobs. Based at Lea Mills in Derbyshire since 1784, John Smedley is the oldest, still-operational knitwear maker in the world. Awarded two Royal Warrants, the company, specialist in exquisite merino, sea island cotton and cashmere, is renowned globally for its craftsmanship and commitment to quality. Its production schedule will open to brands from April 2024, for the forthcoming Spring/Summer 25 season, for the first time in more than 40 years.

Ian Maclean, MBE Managing Director of John Smedley, commented: “John Smedley is spending upwards of £3m to install cutting-edge Shima Seiki machinery in its factories. It’s a generational change in its manufacturing capabilities, enabling us to serve our own needs, and those of our clients. Brands internationally can work with us as partners and benefit from our skills and experience, honed over generations. Our commitment to responsible manufacturing makes our proposition good for brands, good for the world, good for everybody.”

Many of John Smedley’s craftsmen and women have been employed by the factory for decades, offering unrivalled expertise on British soil for third-party brands. The spectrum of manufacturing ranges from fine, 19-micron gauge knitwear to chunky fisherman sweaters.

Further investment

This year, a further £1.5 million will be invested by John Smedley to conclude renovations on its existing manufacturing site. This includes a large expansion of its design and new product development team particularly investing in new technology to program and develop designs.

It also includes relocating and expanding its wash and dyehouse functions. Brands can choose from more than 70 fibre and colour combinations each season: its on-site dyehouse offers unlimited possibilities in terms of colour development.

A pioneering new programme, launched in partnership with Yorkshire-based textile recycling mill Iinouiio, will turn waste yarns into new ones. These new fully recycled and recyclable fibres will launch first on the John Smedley channels from October 2024 and will be made available to external brands from the Autumn/Winter 25 season onwards.

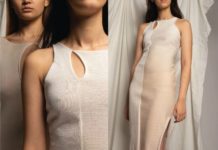

British brand DAKS has committed to bringing its manufacturing back to UK shores, in partnership with John Smedley. A 12-piece knitwear collection, launching for Spring/Summer 2025, will be made at John Smedley under a collaborative label. It is a celebration of heritage meets innovation on British soil, the company says.

By reopening its third-party production schedule, John Smedley hopes to inspire more brands to make goods closer to home. In the 1980s, prior to the manufacturing exodus that saw many companies move production to the Far East, the company created knitwear for luxury labels including Burberry, Paul Smith and Vivienne Westwood.

Responsible production and sourcing

John Smedley is committed to responsible production and sourcing. A fully transparent, traceable supply chain sees its merino and British wools sourced from farms in the UK, where fibres travel less than 300 miles from field to the Derbyshire factory, and New Zealand, which John Smedley has partnered with for more than 50 years and follows the highest ZQRX standards.

Smedley’s Sea Island Cotton and silk, which are offered as standalone fibres and cashmere blends, follow a similar sourcing pattern with cottons from California. Cashmere is sourced from the Upper Alashan regions of inner Mongolia before being spun by specialists Zegna Baruffa whom John Smedley have been working closely with for over 25 years. All cashmere fibres are GRS (global recycle standard), SFA (sustainable fibre alliance) certified.

Aligning with the Fashion Industry Charter, and the United Nations ’Framework Convention on Climate Change, John Smedley is committed to reducing its greenhouse gas emissions by 30% within the next decade, achieving net-zero by 2050. All production runs for third-party brands will follow the same strict, sustainability protocols.

John Smedley

John Smedley Ltd is the oldest continuously operating manufacturer in the world, producing fine gauge knitwear from its Lea Mills, Derbyshire factory since 1784. Crafted from the finest noble fibres of Extra Fine Merino Wool, John Smedley’s Sea Island Cotton, and other luxury blends.

John Smedley’s menswear and womenswear ranges are available worldwide via its stand-alone retail stores in St James’s and Mayfair, London, and in Tokyo, Yokohama and Kyoto, Japan. The full collection can be seen at johnsmedley.com. Exports are made to over 47 countries worldwide via international wholesale partners such as Mr Porter, Selfridges, Harrods, Harvey Nichols, Isetan, Di Bijenkorf, and Le Bon Marche.

Over the years, John Smedley has supported and collaborated with many leading designers to champion British manufacturing including Vivienne Westwood, Lou Dalton, Sacai, and Comme Des Garcons. In 2020, Ian Maclean, Managing Director of John Smedley Ltd and eighth-generation family member, was awarded a MBE for services to the UK textile industry and the Covid-19 response. John Smedley holds two Royal Warrants of Appointment for the manufacturing of fine knitwear.

To register manufacturing interest, brands can contact Jess Mcguire-Dudley at [email protected].

Subscribe To Our Newsletter

Join our mailing list to receive the latest news and updates from our team.